On September 6, the IAA Mobility started in Munich. Thomas was also represented with its own booth. The company presented key innovations in internal combustion engines and alternative drive systems with which it is shaping the future of mobility alongside some of the world’s leading car manufacturers.

The Customer Unit Mobility Solutions develops forward-looking solutions for its partners in the automotive sector. It is driving product innovation in four application areas. Thomas’ main focus is on electrified vehicles and how to make the classic combustion engine cleaner. This includes technologies that aid compliance with increasingly strict regulations on exhaust emissions such as EURO 7 and products that are suitable for alternative fuels. Last but not least, the company also operates in the field of chassis technology.

ePowertrain: Thomas moves hybrids and e-cars

When it comes to the ePowertrain, the Customer Unit Mobilty Solutions is active in several segments. The TS28 transmission solenoid – a proportional solenoid – is already in series production and set to be installed in numerous hybrid vehicles. It makes it possible to control automatic transmissions with maximum efficiency. Thomas also focuses on the issue of thermal management, particularly as batteries used in hybrids and purely electric vehicles have to be systematically cooled or heated during the charging process and when driving. The corresponding cooling circuit, for example, relies on coolant valves. Development is forging ahead in this respect, including switch valves, control valves, and mixing valves. Valve technology has considerable market potential. This is because it is not limited to the battery environment but can do the job in just about every type of cooling circuit. “Our valves regulate and mix cooling flows extremely precisely and guarantee our partners the performance they need,” explains Michael Hinn, project manager at Thomas. “We are also planning a kind of valve construction kit. This will allow our products to be integrated into their systems quickly and easily, which will significantly reduce the time needed for integration projects.”

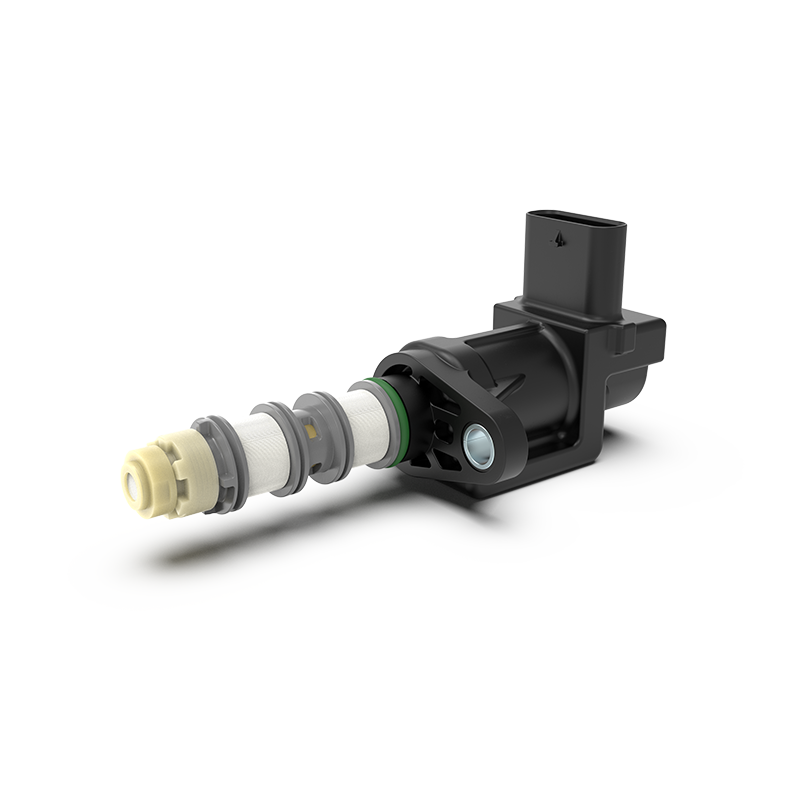

Thomas highlight: Oil control valve with integrated sensors for a major German manufacturer

The valve experts are pursuing their “Sense. Think. Act.” strategy in developing their diagnosable, smart oil control valves. Integrated sensors help the system to monitor whether the valve is opening and closing as specified. The engine control unit quickly detects potential failures and alerts the driver that a visit to the workshop is needed. In this way, smart oil control valves make a vital contribution to compliance with the much stricter emission standards of the future. They also protect components by ensuring optimum lubrication of key engine components.

The four Strategic Fields and their innovations

Powerful pump systems for Emission Management

Demand for electronic components is growing, and not only for exhaust systems. This becomes evident when we consider the area of emission management: with its tank leakage module, Thomas already offers a pump and valve system that detects the most miniscule leaks in the vehicle’s tank. This prevents fuel vapors escaping from the tank, making it a key component for compliance with emissions regulations.

Thomas‘ work on pumps for the CatVap system is particularly ground-breaking. This is a thermal management system for exhaust gas that utilizes the catalytic combustion of fuel to efficiently increase the temperature of the exhaust gas combined with low emissions. Particularly during cold starts and in overrun mode, the temperature of the exhaust gas has to be kept high in order to comply with future emissions standards. The Customer Unit Mobility Solutions is already developing smart pump systems with a communication interface and diagnostic function that are capable of handling a wide spectrum of dosages.

Already developing smart pump systems with a communication interface and diagnostic function.

The trend towards fully active Chassis

Along with the ePowertrain and Emission Management, Thomas is also devoting a great deal of attention to the area of chassis technology. The keywords here are: fully active chassis and level control. This is because automatic adaptation to road conditions and fast level control are becoming even more important. This is partly because of the desire for greater comfort, and partly because in future it will be necessary to protect the most valuable component in electric cars – the battery – from unnecessary shocks and damage. The company has recognized this need and its experts are currently hard at work developing new motorpump units. They could soon be used in active chassis to achieve the fast response that is needed and, together with the control unit, ensure optimum road holding at all times.

Intelligent systems for Alternative Fuels

In its fourth application area, Thomas develops fuel pumps for alternative fuels. Its fuel pumps can already be found delivering, regulating, or metering fuel in many vehicles. For example, the company is one of the main suppliers to one of the world’s market leaders in fuel metering and has also gained a strong foothold in the Chinese market. But the future belongs to alternative fuels. Thomas expects e-fuels, methanol/ethanol blends and power-to-liquid fuels will soon be competing to win favor with manufacturers and customers. Against this backdrop, it is currently expanding its portfolio of fuel pumps to include modular systems, so that the perfect pump can quickly be supplied for all customer applications.

Thomas is also involved in the WaVe (“WAsserstoffVErbrennungsmotor”) project, which brings together major industrial partners under the aegis of the German Federal Ministry for Economic Affairs and Energy (BMWi). The aim of the project is to develop a prototype for a hydrogen-powered, medium-sized commercial vehicle by 2024. The company is contributing its extensive expertise in shut-off and control valves.

A powerful development partner with fresh ideas

These examples all demonstrate Thomas’ in-depth understanding of the market and the needs of vehicle manufacturers, together with its ability – even in times of radical change – to meet the high standards that it sets itself when it comes to technology.

„

We will continue to provide our development partners with the best solutions for their needs. Our ideas provide vital momentum, particularly at the interface of mechanics, electronics, and sensor technology. We are determined to play our part in shaping the mobility of the future.