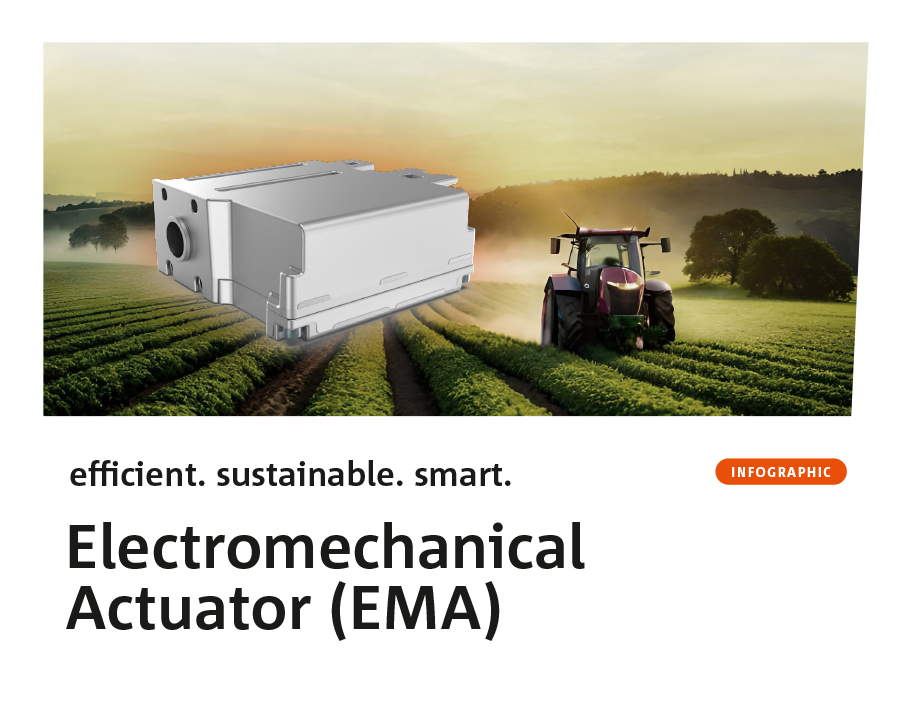

Agricultural technology is facing increasingly complex demands. In addition to delivering ever greater precision, it has to be capable of conserving resources. After all, the agricultural industry is under immense pressure to raise efficiency levels, particularly against the backdrop of spiraling prices – and Green Productivity is one of the hottest topics around. Armed with its electromechanical actuator, or EMA for short, Thomas is playing its part in boosting the overall performance of agricultural machinery.

Electromechanical Actuator (EMA)

Essentially, the EMA is a smart pilot control unit for small and medium-sized main stages with flows of up to 200 l/min, such as those found in small to medium-sized tractors or other agricultural machinery. The actuator offers exceptionally high repeatability, precision, and dynamics as regards the pilot control of the main spool. It is CAN-compatible, diagnostics-capable, and, last but not least, durable. In fact, it can complete more than ten million full actuation cycles without any significant transmission wear.

The EMA thus offers considerable advantages for manufacturers and users alike. A key benefit, for example, is the time it saves during the development stages and it can be easily integrated into existing systems or combined with assistance systems thanks to Thomas Software Control (TSC). It also paves the way for more compact hydraulic systems and provides greater flexibility with regard to design. What is more, production becomes less complex as the EMA does not require an additional low-pressure supply circuit. And in daily use, the system scores with optimized noise development.

More robust, fuel-efficient, and environmentally friendly

The advanced technology of the EMA pays off for the agricultural business as well as for the environment – because it improves the efficiency of the hydraulic system and thus also the machine and increases productivity. Several features contribute to this: The control of the EMA is much more precise than that of conventional pilot control units. The virtually hysteresis-free control, as well as the fast and precise control, increase productivity and enhance the safety of your machine. All in all, this helps to save fuel and reduce the machine’s CO2 emissions. Which shows once again that even the smallest component can make a contribution to increasing efficiency – provided the technology is right!