Even after the conclusion of the three-year “Bauen 4.0” research project, in which Thomas took part, the collaboration is continuing to bear fruit: Jan Julius Stein, Director Development Testing, and Michael Diehl, Test Engineer Development Testing, used their visit to TU Dresden as an opportunity for a field test.

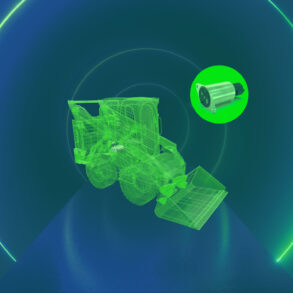

From test bench to building site

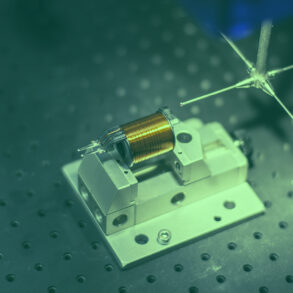

The “Bauen 4.0” joint project saw Thomas provide the Electrohydraulic Actuator (EHA) and Integrated Pilot Head (IPH) for the Liebherr test excavator. As a sub-supplier of off-highway solutions for Tier 1 suppliers and OEMs, Thomas only rarely gets to see what goes on in the end customer’s system. Developers at Thomas can use professional, high-resolution measuring technology in its Testing department to measure the tiniest irregularities such as pressure oscillations. Although they study individual components such as main control valves (MCVs) on the hydraulics test bench, they have to manage without factors like real-life loads (e.g., an excavator boom) that could influence the system. “We wanted to see for ourselves how much sensitivity you could get in the excavator’s controls and whether its actuation and control were ideally configured for the user,” says Michael Diehl, Test Engineer Development Testing.

Digital (remote) control

Cutting-edge STA (Sense. Think. Act.) products like the EHA, which communicates via the CAN bus on the construction equipment, enable a direct connection to the Electrohydraulic Actuators using a laptop. This allows the machine’s settings to be fine-tuned while it is running.

„

It’s highly impressive how precisely and easily an electric construction machine fitted with our STA products, such as the Liebherr excavator, could be controlled after we had finished our investigation and adjustments. This certainly won’t have been our last visit to TU Dresden’s machinery facility!

We are looking for you!

You are a development engineer who enjoys hands-on work?

Join the team Thomas!