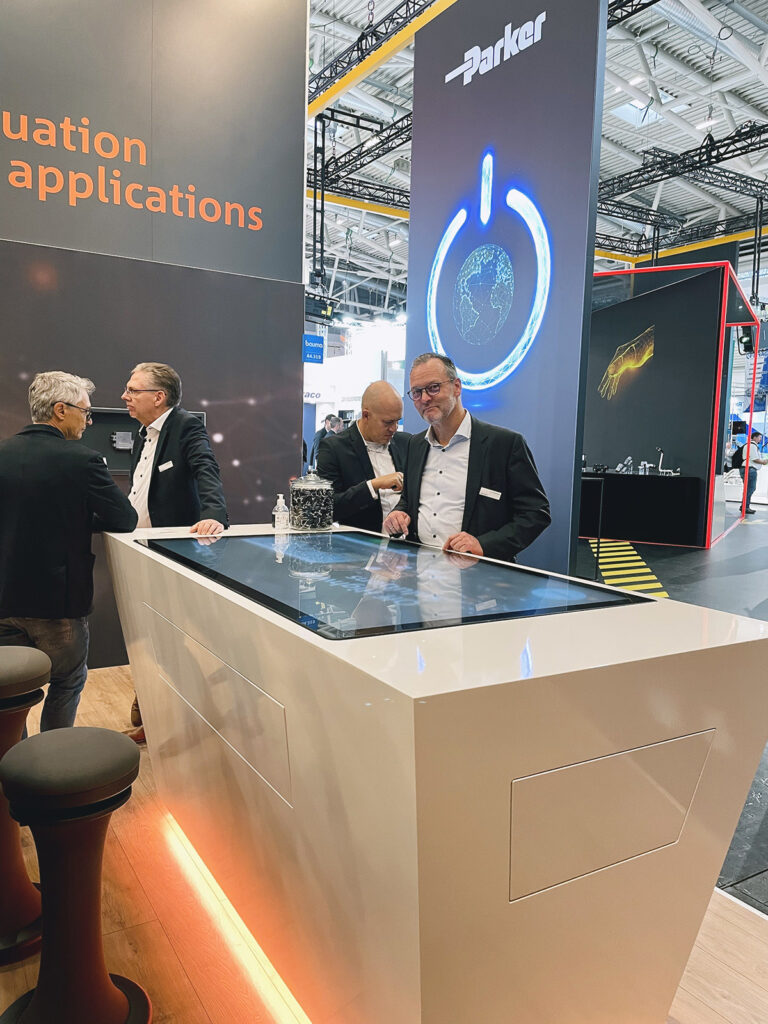

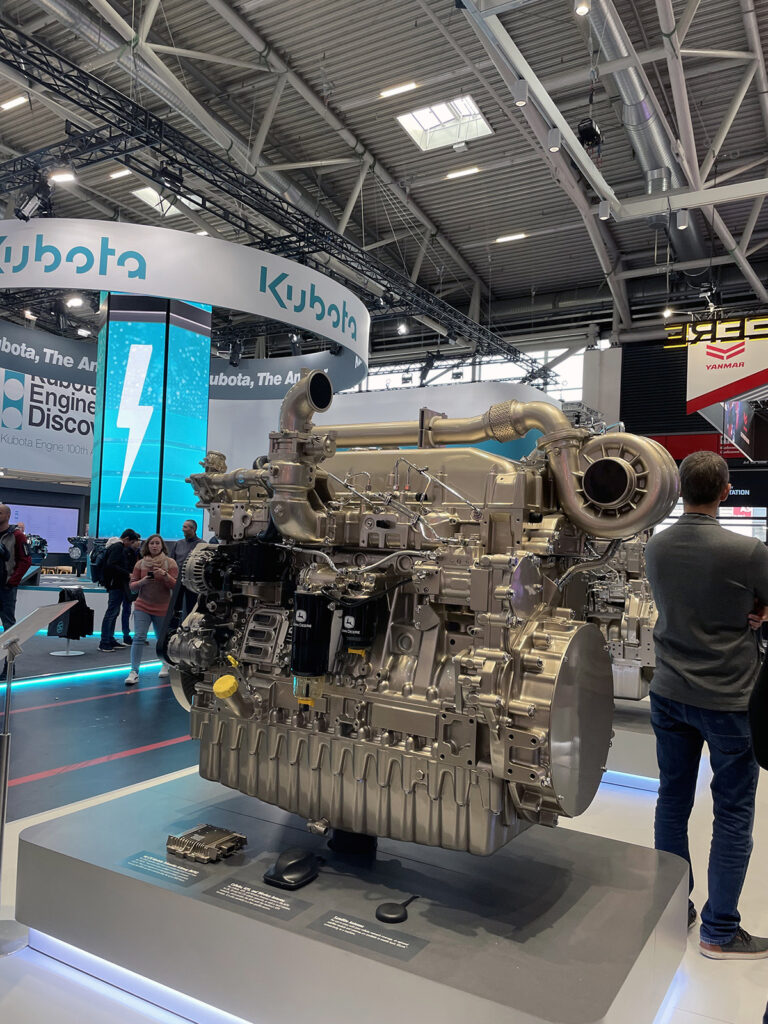

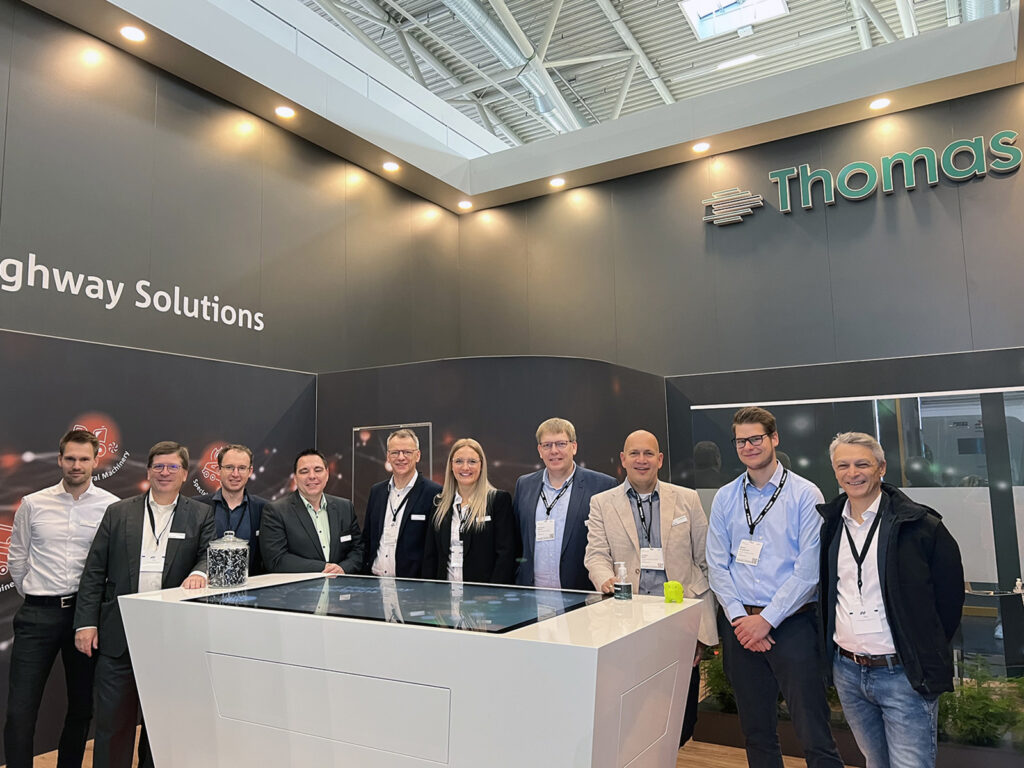

More than 3,000 exhibitors presented their innovations at bauma 2022 in Munich. Thomas was also represented at this year’s trade show, the most important event of its kind for the international construction machinery sector. Embracing “Smart actuation for smart applications“ as its motto, Thomas showcased a range of products that address key issues discussed throughout the industry. The company’s electrohydraulic PPCD08 NG and PPCD09 NG valves, for example, are capable of unlocking new opportunities when it comes to raising efficiency levels. And the new IPH proportional valve, a unique offering within the market, makes it possible to design machines that are more compact than ever before.

bauma Munich

Oct. 24-30, 2022

This year’s trade show focused on topics such as “construction methods of the future,“ “autonomous machines,“ and “the digital construction site.“ Indeed, one could sense that the issue of digitalization is at the top of the agenda. As a long-standing supplier and development partner to the industry, Thomas is thoroughly committed to delivering state-of-the-art valve technology tailored to the latest standards and requirements. Its portfolio boasts technology that is “electrified,“ “connected,“ and “cost- efficient.“ There were many highlights to discover, including a world premiere.

Cost-efficient: CPA and IPH

The Munich-based event, for example, provided Thomas with the perfect platform to present details of its Compact Pilot Actuator (CPA), which is scheduled to go into production by the end of 2023. Compact by name, compact by nature: this pioneering pilot valve combines the benefits of outstanding performance and a very small footprint. It is the first proportional control valve for the off-highway sector to come in a width of just 26 mm. For manufacturers of small construction machines such as mini excavators this means that the main control valves can be dimensioned smaller – and considerably so. In addition, the CPA helps to speed up assembly in the factory, as it is attached with only a single screw instead of two, as was previously the case.

Very small footprint: Compact Pilot Actuator (CPA)

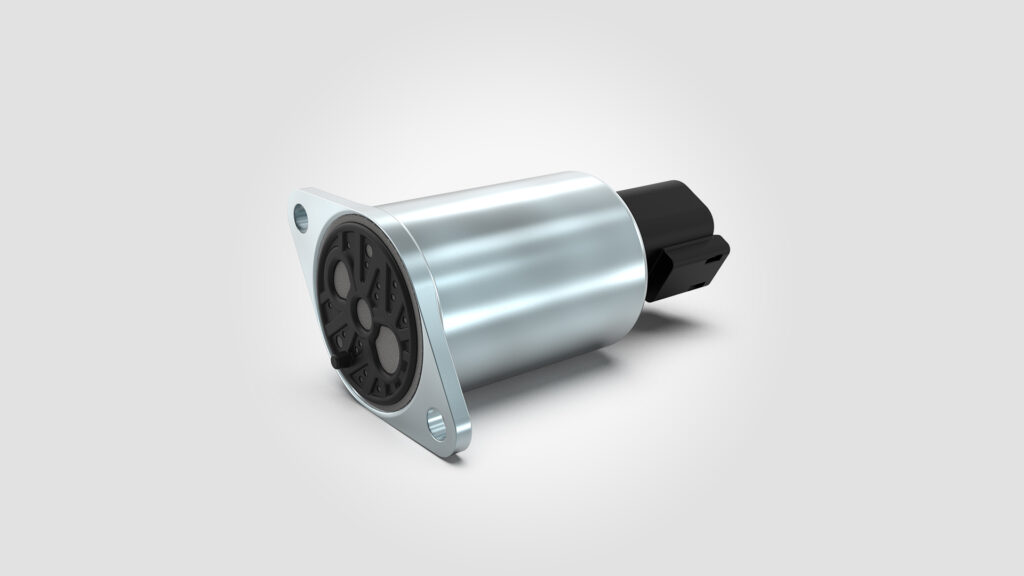

The Integrated Pilot Head (IPH) also represents a new valve concept. Thomas developed it for one of Germany’s leading mobile hydraulics manufacturers. At present, no competitor can offer comparable technology. As a unique feature, the proportional pressure-reducing valve brings together the full range of hydraulic functions within the solenoid itself and does not require an attached valve sleeve. As a result, it is extremely compact and allows manufacturers to further reduce the space needed for installation. Despite its small footprint, it is capable of delivering a flow rate of 2 l/min – the perfect choice for the segment of compact construction machinery targeted by the company. What is more, the connection interface does not require any elaborate drilling – another key advantage. Thus, production and assembly are less complex and time-consuming. All hydraulic connections are also protected by an integrated filter element, which prevents system contamination.

New valve concept: Integrated Pilot Head (IPH)

Electrified: PPCD08 NG and PPCD09

Based on market-proven technology, the latest generation of electrohydraulic PPCD08/09 valves are also likely to have attracted attention at bauma 2022. The PPCD08/09 NG are used to actuate the clutch and are ideal for small machines and tractors due to their space-saving dimensions. They ensure precise control and smooth movement, even when shifting under load. Last but not least, the valves are designed to be robust and dirt-resistant, thus meeting the extreme demands of the off-highway market.

Connected: electrohydraulic and mechatronic systems

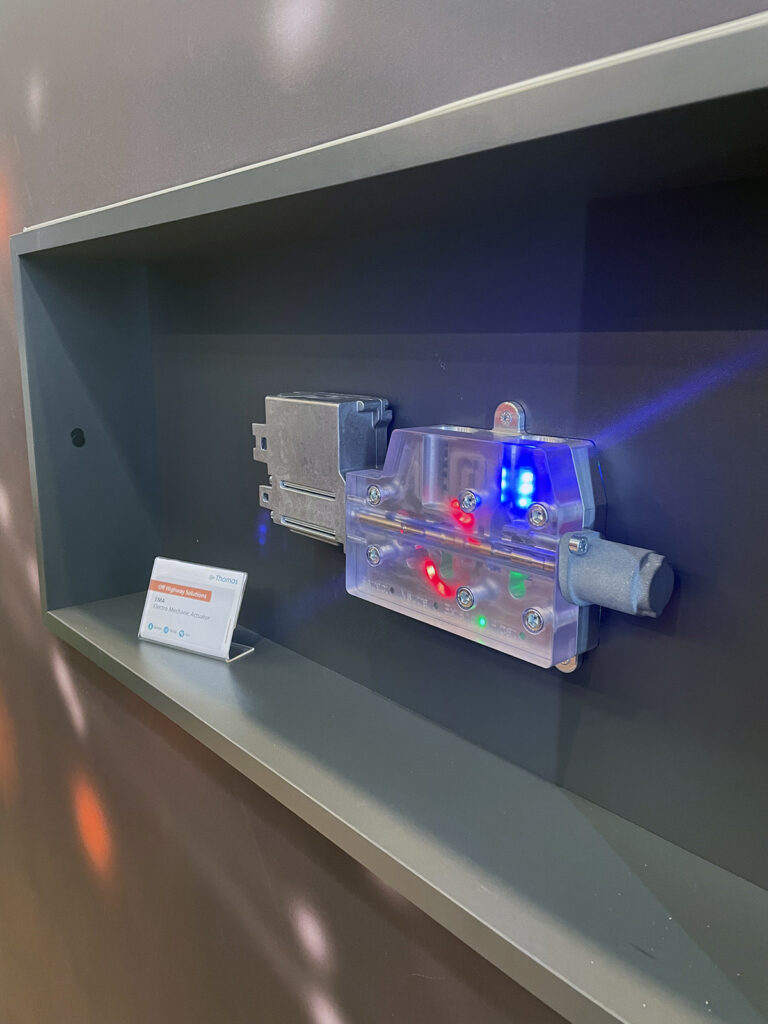

Tailored to the requirements of construction machinery, cranes, and steering applications with particularly high standards in respect of system safety and reliability, the Electro Hydraulic Actuator (EHA) boasting safety functions according to DIN EN ISO 13849 and the Electro Mechanic Actuator (EMA) were two other Thomas highlights to be showcased at bauma. Both are equipped with built-in intelligence that is connected to the higher-level system and performs the task of system status transmission. Thus, the system not only receives essential data for the purpose of control and optimization but can also ensure that all sensors integrated in the EHA and EMA are working correctly at all times.

The EHA and EMA are CAN-controlled units for hydraulic directional spool valves. Fast reaction times, high precision, and smooth motion control are among their key advantages. In contrast to the EHA, the EMA is controlled mechanically; no pilot hydraulic control circuit is required. Instead, a single cable to the control unit is sufficient, which reduces system complexity. Therefore, the EMA is suited in particular to applications calling for perfect system stability in combination with superior motion dynamics.

Cost-efficient, electrified, connected: Thomas presented several solutions at bauma designed to make systems smarter, more compact, more efficient, and more powerful – and deliver value for money.