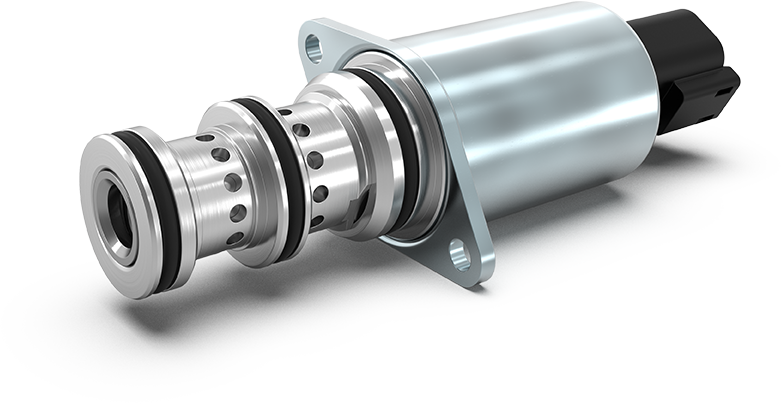

Automated gear changes make driving a pleasantly simple experience for users of agricultural and construction machines. Juri Buss, Product Manager Off Highway Solutions at Thomas, explains how clutch transmission valves contribute to this and what the key factors are.

Product properties

Optimized spool guidance for best hysteresis

CFD optimized geometry for maximal flow capability

Reduced magnetic sticking during clutch disengaging

Filter screen for large particles

Hardened spool/sleeve for best performance in contaminated Oil

Flat flow-map for flow independent control pressure

Reduced leakage to minimize effect of silting

Optimized spool guidance for best hysteresis

CFD optimized geometry for maximal flow capability

Filter screen for large particles

Hardened spool/sleeve for best performance in contaminated Oil

Flat flow-map for flow independent control pressure

Reduced magnetic sticking during clutch disengaging

Reduced leakage to minimize effect of silting