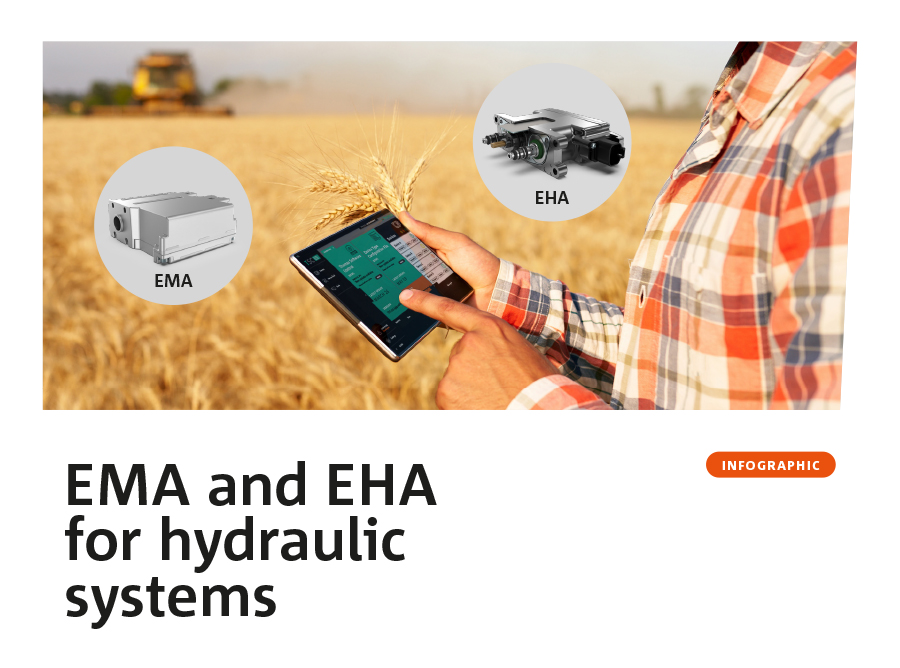

Digitalization has become firmly established in many areas of agriculture: Dairy cows have not been milked by hand for a long time now; robots are helping to distribute feed or clean surfaces; and users are monitoring, connecting up, and automating their agricultural machinery. The digital transformation is all about boosting efficiency and optimizing the use of resources. In the agriculture sector, smart farming is switching the focus from the product to the process as a whole. The tractor of tomorrow has to fit into this infrastructure. Smart actuators give manufacturers the functionality they need to make effective digital hydraulic systems.

More productivity

“Smart farming is aiding yield growth,” says Jürgen Roth, Key Account Manager Off Highway Solutions. “It allows users to apply fertilizer in a more targeted way or dose out the water for irrigating land more precisely. Optimizing the use of resources – water, fertilizer, pesticides, energy, and labor – is not only sustainable, it also saves money. In this way, farmers are increasing their productivity and playing a coordinating and monitoring role in the work being done with their digital machinery.”

The use of decentralized control units is an attractive option for manufacturers of agricultural machinery and Off Highway systems, as they regulate workflows precisely and independently of external influences. For example, controlling the force or position of hydraulic lifting gear allows the working depth of a plow to be adjusted conveniently and safely, enabling uniform plowing.

Benefits of electromechanical actuators

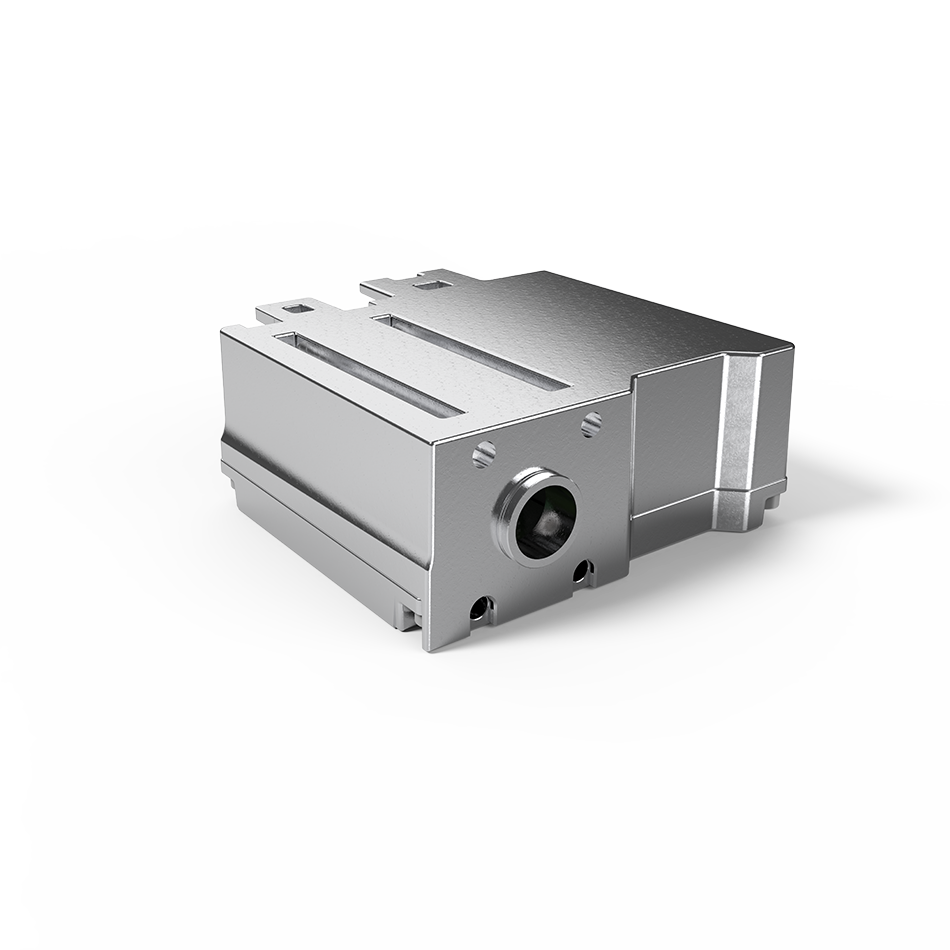

Electromechanical actuators (EMAs) are self-contained control devices that are used to actuate and position the main spool inside hydraulic directional control valves. Equipped with reliable, state-of-the-art electronics, the corresponding software, and a robust mechanical system, an EMA enables fast and accurate control, while the mechanical actuation process means that this can be done without any vibration risk or hysteresis whatsoever.

Smart actuation – a step forward

Thomas commenced series production of its EMA in summer 2020. “The EMA is easy to integrate into a hydraulic system, with minimal parameterization of the directional control valve,” explains Juri Buss, Product Manager Off Highway Solutions. “This allows flow rate characteristics to be configured to our customers’ individual requirements.”

The EMA has been developed in line with Thomas’s “Sense. Think. Act” strategy. The company is picking up on the current trend within the market toward safe, secure, and smart-working machinery.

The electromechanical actuator offers several advantages over its conventional counterparts:

Features

- Positioning speed 80 mm/s

- Actuating force 240–340 N

- Working stroke up to 22 mm, repeatability ±6 µm and resolution 6 µm

- Thermal overload protection

- Actuation via CAN bus

- Developed and certified in accordance with DIN EN ISO 13849

Benefits of the EMA from Thomas

„

With all its benefits, the EMA is a step forward for agricultural machinery technology. It makes electrohydraulics more productive in support of digital transformation. Developing smart products that bring customers real added value is key for Thomas.