In October, the International Suppliers Fair (Internationale Zulieferbörse – IZB) was set to attract vehicle manufacturers and automotive suppliers to Lower Saxony. As a leading development partner to OEMs, it was obvious that Thomas has been part of the action at the leading European trade show for automotive industry suppliers. The company’s Mobility Solutions unit presented numerous innovations from its four strategic fields: ePowertrain, Chassis, Emission Management, and Alternative Fuels.

One thing is certain: The electrification of the powertrain is a crucial element in achieving climate-friendly transport solutions. This was a major focus of the exhibition in Wolfsburg, such as alternative fuels. Additionally, however, the automotive industry is constantly looking for ways to also make gasoline and diesel engines even more efficient and thus more climate friendly. The Thomas exhibition booth has covered all these issues and showcased innovative solutions, many of which are equipped with smart features that reflect the company’s “Sense. Think. Act” approach.

“The IZB was as an excellent platform that allows us to demonstrate that in times of technological disruption, we are developing exactly the products that vehicle manufacturers need,” explains Martin Schmidt, Director Market and Product Management Mobility Solutions at Thomas. “In the process, we are resolutely pursuing the system approach and delivering complete solutions comprising mechanical, electronic, and sensor components, whether for combustion engines or electrically-powered vehicles.”

Innovations for hybrid and electric vehicles

In the strategic field ePowertrain, for example, Thomas offers two special products. In hybrid and electric vehicles, a modular thermal management system ensures optimum temperature control of the battery and other powertrain components. Developed as a modular system, its shut-off, mixing or control valves with optional diagnostic function can be readily adapted to specific customer requirements. The second focus area consists of solenoids and valves for transmission applications, where the manufacturer offered technologies that are already efficiently controlling the automatic transmissions of many hybrid vehicles.

Meeting Euro emission standards with Thomas solutions

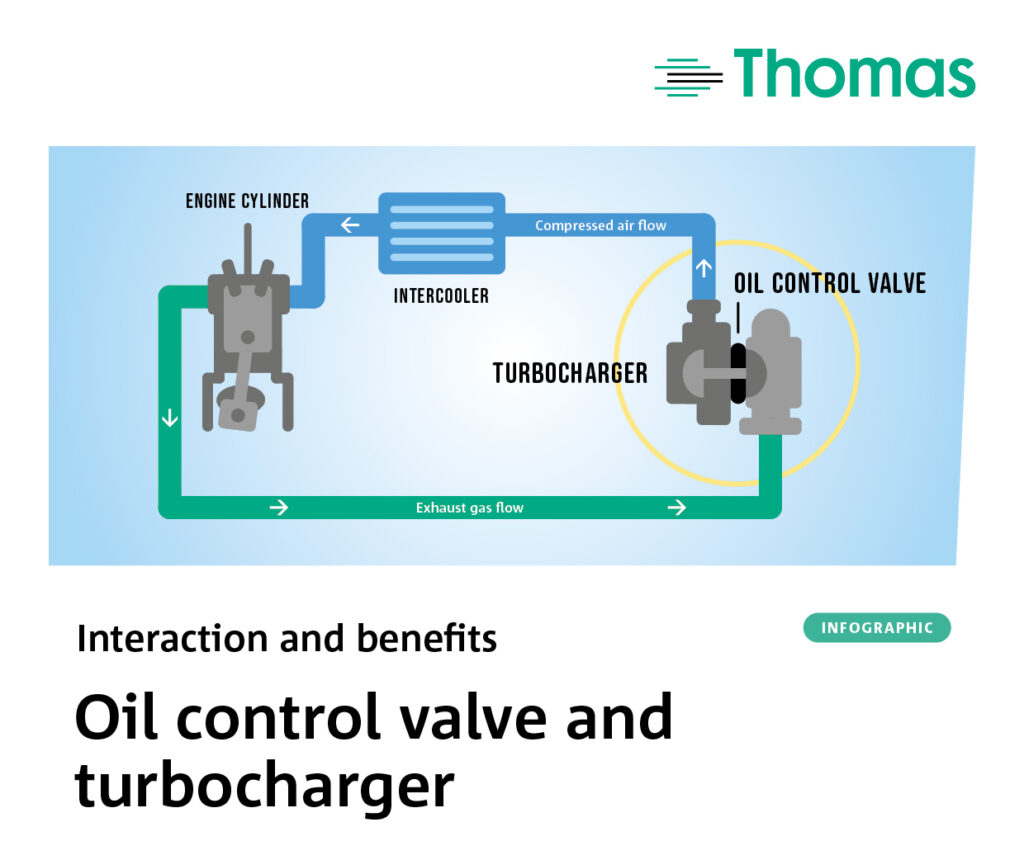

For combustion engines, Thomas presented a true highlight – the new oil control valve it has developed for a major German carmaker.

In the application in question, the electronic valve, which is optimally protected against negative environmental influences, ensures precise and active lubrication of the turbocharger. It also makes sure that the oil flow is shut off quickly and efficiently in the overrun phase. This means that unused oil cannot reach the exhaust-gas side and consequently, cause emission values to deteriorate. The oil control valve’s “secret weapon” is its diagnostic capability. An integrated sensor constantly informs the engine control unit about the status of the valve. The ECU therefore immediately detects a malfunction and alerts the driver accordingly. Incidentally, Thomas is using a new kind of process for the plastic sheathing of the oil control valve that is suitable in principle for any heat-sensitive electronics.

The new oil control valve

Perfectly coordinated, cutting-edge chassis technology

Modern chassis technology plays a key role in ride comfort and protects the battery of electric cars from shocks and damage. At the IZB, Thomas has therefore introduced trade visitors to a new motor-driven pump unit for fully active suspension systems that already factors in the next evolutionary stage, i.e., autonomous driving. The smart all-in-one solution has integrated power electronics, communicates with the vehicle control unit via LIN or CAN, and noticeably reduces the vehicle’s lifting, rolling, and pitching. It also facilitates automatic vehicle level control that is extremely dynamic, quiet, and reliable.

Reliably comply with emission standards

In the field of emission management, Thomas grabed the headlines with no fewer than three products: The new tank leakage module (TLM), for example, is a significant component with a view to meeting Euro 7, because it can generate positive or negative pressures and accurately detect pressure changes in the tank. Regardless of external factors, the engine control unit detects leaks of any size with the help of the TLM. At the IZB, Thomas has also showcased its fuel metering systems, which can be readily integrated without major modifications as stand-alone solutions into parking heaters, auxiliary heaters, or fuel supply units for exhaust gas after-treatment systems. And last but not least, the Thomas booth displayed the company’s proven freezing-resistant SCR systems for AdBlue metering.

Systems for alternative fuels

The exhibition in Wolfsburg also payed particular attention to the topic of alternative fuels. Nevertheless, e-fuels, methanol-ethanol blends, power-to-liquid fuels, and hydrogen do impose completely new requirements on the fuel system. Thomas has therefore modified its metering system for parking and auxiliary heaters in such a way as to take account of these requirements. But that’s not all, because in Herdorf, the company is also driving the development of hydrogen-capable technologies. In Wolfsburg, the Thomas team provided information on a control valve prototype. The valve precisely regulates gaseous hydrogen to a pressure of 5 to 30 bar and makes it available for combustion. It is characterized by its easy regulability and provides an extremely stable control pressure. It could be used in passenger cars, commercial vehicles and stationary applications.

„

At the IZB we’ve discovered the current trends and developments in the automotive industry. This generates new impulses for us. In addition, we were able to exchange ideas with the other participants and have many interesting conversations. All in all, it was simply a successful trade fair at which we were able to present not only our wide-ranging product portfolio, but also Thomas.