Understanding customer needs and spotting the latest market trends – needless to say, these tasks are all part and parcel of the “homework” done by Thomas’s development and sales teams. Thomas Jakob, Product Manager Off Highway Solutions, thinks that there are currently three main trends that will have a significant impact on the agricultural and construction machinery technologies of the future: efficiency, autonomy, and connectivity.

Greater efficiency through electrification

From the perspective of social policy, environmental protection and sustainability are two key issues that are influencing the development of technology. No fewer than 197 countries committed to cutting their carbon emissions under the Paris Climate Agreement, which emerged from the 2015 UN Climate Change Conference. Initiatives such as the European Green Deal are pursuing this objective within Europe, while the emissions generated by diesel-powered construction machinery are also being increasingly regulated at international level. For instance, the U.S. Environmental Protection Agency (EPA) wants to combat air pollution with its Tier 4 specifications, while China has lowered its permitted emission thresholds very sharply in recent years with the help of its CN Stage VI regulations. It is becoming clear that environmental protection legislation across the world is fueling the trend toward increasingly efficient machinery.

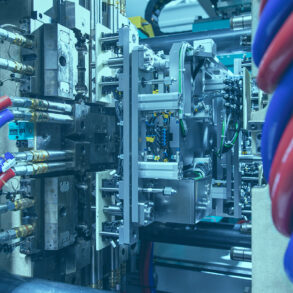

“Modern hydraulic systems offer ample scope for improvement,” Thomas Jakob explains. “Lighter materials, improved valve technologies, electrification and power-on-demand systems can play a major role in generating efficiency savings.” With the pilot control of construction and agricultural machinery, for instance, electrification – e.g., using the Electromechanical Actuator (EMA) – can increase efficiency through precise control and regulation. Energy demand is regulated more effectively, thus saving energy, because the combination of state-of-the-art, electronically pilot-controlled valves or actuators supplies the precise volume flow desired. Among construction machines weighing less than 6 metric tons, there is an increasing trend toward all-electric machinery, with most manufacturers already offering fully electric models or working on corresponding concepts.

Thomas Jakob has this prediction to make: “If other initiatives are added to the mix too, such as that proposed by the Hauptverband der Deutschen Bauindustrie (HDB) to consider CO2 potential when awarding construction contracts, then all-electric construction machinery will gain market share. I’m also seeing a number of e-mobility trends: The performance levels of modern batteries will push lightweighting and high-efficiency drives increasingly into the spotlight.”

Electromechanical Actuator (EMA)

Autonomy for enhanced safety and productivity

Autonomous technologies boast a greater level of safety in use as well as higher productivity thanks to improved processes and more precise working. Workflows can be planned down to the tiniest detail, coordinated with one another, or run simultaneously.

Many farmers are complaining about an ever-greater workload and a lack of young talent coming through. For example, the solution encompasses fully automatic feed systems in which individual pieces of equipment perform their work while navigating autonomously. Rather than still being a pipe dream, these technologies have been a day-to-day reality in modern agriculture for some time now.

Safety is the top priority with construction machinery. Sensor systems are used that can detect obstacles or hazards in real time and respond to them, e.g., to avoid a collision, and there are additional safety requirements to meet where the electronics intervene directly in a machine’s operation. All of this is made possible thanks to the electrification of the hydraulic pilot control. Thomas’s hydraulic actuators such as its EHA 2.0 with integrated failsafe valves boast additional features and properties that fulfill the highest safety requirements – up to Safety Performance Level D depending on their intended use and the customer’s system. Thomas has developed these products with its customers in mind specifically for autonomous and partly automated applications. Withits current product range, the Thomas Group offers OEMs and Tier 1 suppliers everything they need to respond to the current trends: innovative, forward-looking technologies that enhance efficiency and productivity and open the door to maximum added value worldwide.

Connectivity for optimum monitoring and analysis

Autonomous construction and agricultural machinery needs connectivity – the digital link with the individual machines – as it allows users to monitor and control their machinery remotely in real time. Remote troubleshooting and fault-fixing are also making agricultural and construction machinery more productive and improving its performance, while machines that have been converted to digital are able to gather and evaluate data continuously. Predictive maintenance allows necessary maintenance work to be planned as required and sources of errors to be identified and fixed promptly, enabling costly machine downtime to be avoided. Here too, our “Sense. Think. Act.” products such as the EMA and EHA form the basis for implementing these features. Specifically, they provide an electrical interface with the hydraulic system in both directions and are capable of logging and processing data and transmitting it to the higher-level control system.

„

Product solutions from Thomas are already helping to make the forward-looking trends of efficiency, autonomy, and connectivity a reality for construction and agricultural machinery and are thus actively helping to shape the future of the off-highway segment.