The Mechanical Engineering Industry Association (Verband Deutscher Maschinen- und Anlagenbau – VDMA) recently reported that China had launched an assault on Germany’s position as global export champion within the mechanical engineering sector in 2020. Boasting a volume of around 165 billion euros, equivalent to 15.8 per cent of the total export volume of global machinery exports, China overtook Germany with its 162 billion euros, that is 15.5 per cent. This was a significant jump, considering that Germany had still been 1.4 percentage points ahead of China in 2019. One of the consequences of such growth: demand for solutions centered around Off Highway applications from technology supplier Thomas, especially from the Far East, is booming.

Shortly after launching the Customer Unit Off Highway Solutions in 2003, Thomas established its first industry contacts through regular visits to trade shows in Shanghai. Thomas has maintained a presence in Shanghai since 2006, steadily expanding its supplier portfolio. Since 2018, company plans to establish a manufacturing facility in China have also become increasingly concrete, particularly as Chinese customers are keener than ever to source products locally. A logical step, given the fact that procuring products from Germany costs time and money, in addition to requiring a great deal of flexibility: shipping, after all, takes six weeks or more. Shipping charges and customs duties also have to be taken into account. What is more, the cost of materials is higher than in China. Therefore, to remain competitive in the long term, a local production facility is essential.

„The main rationale behind our decision to establish our own production plant in China was our desire for greater customer proximity and more flexibility throughout the entire supply chain. China is experiencing enormous economic growth and our customers are highly innovative, especially in the off highway sector. We want to participate in local and global competition for the best technologies and serve our Asian customers even better from a local base,“ explains Christoph Thomas, Chief Customer Officer. „Looking back, the effects of the pandemic in particular have further reinforced our decision,“ he adds.

With an experienced partner at its side

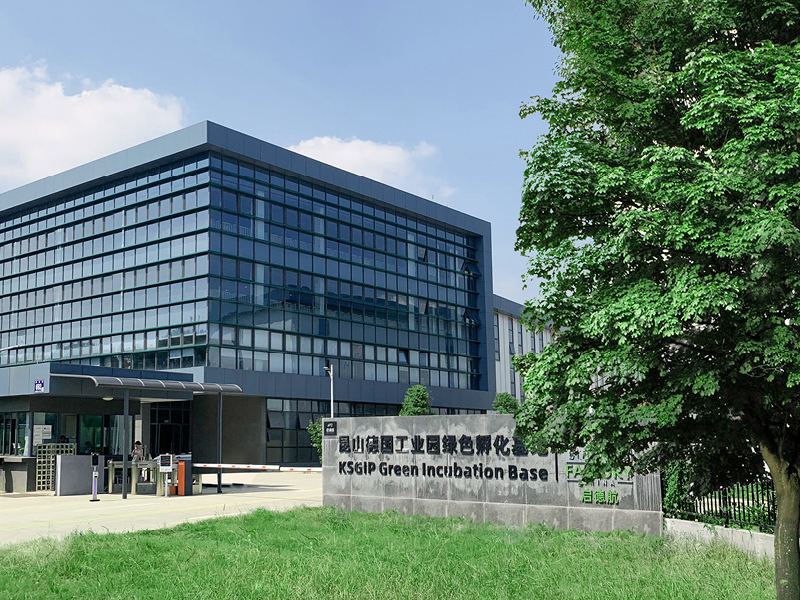

A service provider with branches in Munich and Kunshan (China) has recognized the needs of German SMEs in entering the Chinese market and offers companies like Thomas a complete package: a German-Chinese team rents out production space and takes care of the central issues of management, financial accounting, administration, and personnel, in addition to supporting the Thomas team in other functions, e.g., in the area of quality management and production. Thomas appreciates this form of support from an experienced partner, as it provides the basis for faster localization and thus reduces commercial risk.

The service provider has a total of 40,000 m² of production space in Kunshan, a city with a population of over two million. It is centrally located in the economic heartland of the Yangtze River Delta about 60 km west of Shanghai.

Thomas will start with 700 m², which will accommodate two production lines from the first half of 2022 and two more from the second half of the year. The service provider sees itself as an „incubator“ for German medium-sized production companies and handles the full range of tasks associated with the establishment and management of a subsidiary up to the stage of transferring operations to the client’s own production branch. With their help, Thomas established its own company in China, Thomas Actuation Technology Ltd. Kunshan, as early as May 2021.

After two to five years, clients such as Thomas usually grow to a size where more than 1000 m² of production space is required. During this time, they achieve independence through the experience they have gained and the networks they have established. Christoph Thomas, Chief Customer Officer, also has long-term plans for Thomas‘ business development in this growth market: „We will continue to invest in expanding our local production capacity in China in order to be able to continuously meet the additional requirements of our customers in Asia. In this context, we will align our decision-making with the strategic approaches taken by our customers and the Chinese government.“

Intercultural teamwork

In addition to economic factors, socio-cultural aspects relating to the German and Chinese mentality have to be taken into account as part of these collaborative efforts. Within the company, Johannes Alessio in Germany and Xiangfeng Zhou in China have been appointed as project managers. Thorough coordination is required in the planning and implementation of the project steps to be executed by Thomas, such as technical production preparation. Despite the time difference of six hours between China and Germany, video conferences are considered particularly important in order to be able to exchange ideas more directly at a one-on-one level. Asked to describe the Chinese way of working, Johannes Alessio, Director Project Management Off Highway Solutions, says, „I find my Chinese colleagues much more willing to take risks than German members of the team. They embrace the principle of „trial and error.“ Decisions are made in a rather authoritarian manner, work is performed quickly and pragmatically, the focus always being on delivering a solution tailored to customer requirements. Of course, this requires a great deal of trust before business transactions are concluded.“

Xiangfeng Zhou, Chief Representative Officer & Sales Manager, describes his view of the German approach as follows: „I perceive my German colleagues to be very thorough and conscientious in their work. First they think and evaluate, then they act. Decisions within the team are made democratically and there are many checklists. Compared to our way of working, completing project steps is slightly slower.“

The German-Chinese Thomas team feels enriched by this cross-cultural interaction. All those involved gain insights into different ways of thinking and working and learn to reflect on their own approach. The team appreciates the benefits of both mentalities and seeks the middle ground between these two worlds: German quality standards also apply to production in China and decision-making processes are more dynamic due to agile project development. In the spirit of the Thomas values of „Integrity, Courage, and Support,“ this is how successful cooperation in the burgeoning market of China is achieved, today and in the future.